We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it. Learn more

How to Polish and Grind Stone Floors - Lavina ELITE Floor Machine

The Lavina ELITE floor machine range is ready to polish and grind concrete, terrazzo and natural stone floors. This article will guide you through the process of operating these floor machines including inspection and maintenance. We will also look at the best grinding and polishing tools to use alongside the ELITE machines.

Tiling Logistics are the UK's only choice for hard floor grinding machines, our professional range has a wide range of customers from small business owners, to cleaning companies, franchises and large companies across England, Wales and Scotland. Questions? Call us on 0121 773 9129.

For advice on other floor restoration treatments, check out our blog or send us a message online.

Lavina ELITE Floor Machine Control Panel

- EMERGENCY button used to stop the motor in case of emergency.

- Potentiometer.Controls the RPM of the grinding plates in a range of 300-900 rpm.

- ON / OFF switch. The switch returns to its starting position after being released.

- Tachometer. Display the RPM of the grinding plates.

Using the machine -

During operation, guide the stone floor grinder across the floor in straight lines. Each line will slightly overlap the last. Maintain a constant speed. Your movement speed should correlate to the necessary time each tool needs depending on their grit size.

Avoid vibrations.

When working dry, check the floor surface periodically for dust accumulation. Check regularly to see if you’re vacuum works properly.

Do not stop the machine while tools are still running as they will mark the surface of the floor.

Stopping the Machine -

Stop the machine gradually until the motor completely stops. Never stop moving the floor machine before the motor comes to a stop.

To stop the stone floor grinder: Turn the ON/OFF switch in position, this will cut the voltage to the inverter.

To learn more about the Lavina ELITE Floor Machine series, read the operator guide for the Lavina L16EU.

As the name suggests, the Quick Change metal bond tools feature fast and convenient tool changes. Additionally, they have a long service life which reduces future expenses.

They feature swift and convenient tool changes, and a long tool life, providing for great long‐term cost savings. The metal bond tools are available in four different bonds for extra hard, super hard, hard, medium and soft concrete, in several grit sizes.

We offer the tools with 1 or 2 buttons or rectangular segments letting users choose the aggressiveness of the cut.

As the name suggests, the Quick Change metal bond tools feature fast and convenient tool changes. Additionally, they have a long service life which reduces future expenses.

They feature swift and convenient tool changes, and a long tool life, providing for great long‐term cost savings. The metal bond tools are available in four different bonds for extra hard, super hard, hard, medium and soft concrete, in several grit sizes.

We offer the tools with 1 or 2 buttons or rectangular segments letting users choose the aggressiveness of the cut.

The Calibra Grinding Discs are one of the most popular tools from Lavina. They are made for removing scratches on hard concrete surfaces. The ideal tool for saving time while on the job as they only need to pass over the surface once. They can be used wet or dry.

The Calibra Grinding Discs are one of the most popular tools from Lavina. They are made for removing scratches on hard concrete surfaces. The ideal tool for saving time while on the job as they only need to pass over the surface once. They can be used wet or dry.

The V-Harr premium polishing pads are mechanical polishing and restoration pads for concrete and terrazzo. We highly suggest dry use. These polishing pads are available in many diameters and grit sizes to accommodate many applications.

The V-Harr premium polishing pads are mechanical polishing and restoration pads for concrete and terrazzo. We highly suggest dry use. These polishing pads are available in many diameters and grit sizes to accommodate many applications.

The Lavina ELITE polishing and grinding machines feature numerous upgrades. The first of these upgrades is an improved water system with 2 valves using water from a tank or different external source. Gravity is left to deliver the water instead of using a pump or misting system. As a result, these stone floor machines excel in wet grinding.

The ELITE machines have a dust-proof grinding head and low-friction chain gear planetary drive. Protection from dust makes the machines easier to clean and lengthens their service life.

They also have better dust collection efficiency when in comparison to older models of the Lavina floor grinding and polishing range. The efficient dust collecting comes from an adjustable skirt and flexible brush on the machine. The vacuum hose connection is also near the dust source.

These floor polishing machines have LED lights in both the front and the back to keep the work area visible during treatment.

The Lavina ELITE polishing and grinding machines feature numerous upgrades. The first of these upgrades is an improved water system with 2 valves using water from a tank or different external source. Gravity is left to deliver the water instead of using a pump or misting system. As a result, these stone floor machines excel in wet grinding.

The ELITE machines have a dust-proof grinding head and low-friction chain gear planetary drive. Protection from dust makes the machines easier to clean and lengthens their service life.

They also have better dust collection efficiency when in comparison to older models of the Lavina floor grinding and polishing range. The efficient dust collecting comes from an adjustable skirt and flexible brush on the machine. The vacuum hose connection is also near the dust source.

These floor polishing machines have LED lights in both the front and the back to keep the work area visible during treatment.

How to Polish and Grind Stone Floors with Floor Machine

Starting the machine - Release the emergency stop. Check the potentiometer ensuring it is set to working speed. When working dry, connect your floor polishing and grinding machine to a vacuum unit. Finally, hold the machine firmly and turn the switch to the ON position.Lavina ELITE Floor Machine Control Panel

- EMERGENCY button used to stop the motor in case of emergency.

- Potentiometer.Controls the RPM of the grinding plates in a range of 300-900 rpm.

- ON / OFF switch. The switch returns to its starting position after being released.

- Tachometer. Display the RPM of the grinding plates.

Using the machine -

During operation, guide the stone floor grinder across the floor in straight lines. Each line will slightly overlap the last. Maintain a constant speed. Your movement speed should correlate to the necessary time each tool needs depending on their grit size.

Avoid vibrations.

When working dry, check the floor surface periodically for dust accumulation. Check regularly to see if you’re vacuum works properly.

Do not stop the machine while tools are still running as they will mark the surface of the floor.

Stopping the Machine -

Stop the machine gradually until the motor completely stops. Never stop moving the floor machine before the motor comes to a stop.

To stop the stone floor grinder: Turn the ON/OFF switch in position, this will cut the voltage to the inverter.

To learn more about the Lavina ELITE Floor Machine series, read the operator guide for the Lavina L16EU.

Recommended Floor Grinding and Polishing Tools

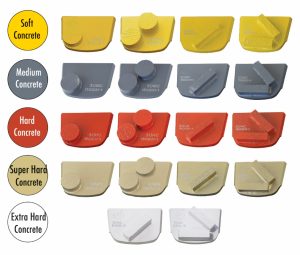

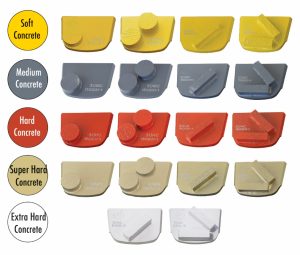

QuickChange Metal Bond Tool System

As the name suggests, the Quick Change metal bond tools feature fast and convenient tool changes. Additionally, they have a long service life which reduces future expenses.

They feature swift and convenient tool changes, and a long tool life, providing for great long‐term cost savings. The metal bond tools are available in four different bonds for extra hard, super hard, hard, medium and soft concrete, in several grit sizes.

We offer the tools with 1 or 2 buttons or rectangular segments letting users choose the aggressiveness of the cut.

As the name suggests, the Quick Change metal bond tools feature fast and convenient tool changes. Additionally, they have a long service life which reduces future expenses.

They feature swift and convenient tool changes, and a long tool life, providing for great long‐term cost savings. The metal bond tools are available in four different bonds for extra hard, super hard, hard, medium and soft concrete, in several grit sizes.

We offer the tools with 1 or 2 buttons or rectangular segments letting users choose the aggressiveness of the cut.

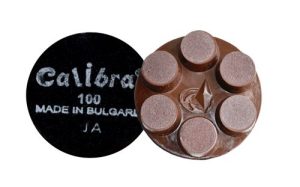

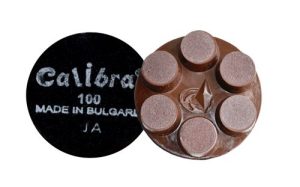

Calibra Grinding Discs

The Calibra Grinding Discs are one of the most popular tools from Lavina. They are made for removing scratches on hard concrete surfaces. The ideal tool for saving time while on the job as they only need to pass over the surface once. They can be used wet or dry.

The Calibra Grinding Discs are one of the most popular tools from Lavina. They are made for removing scratches on hard concrete surfaces. The ideal tool for saving time while on the job as they only need to pass over the surface once. They can be used wet or dry.

V‐Harr Premium Polishing Pads

The V-Harr premium polishing pads are mechanical polishing and restoration pads for concrete and terrazzo. We highly suggest dry use. These polishing pads are available in many diameters and grit sizes to accommodate many applications.

The V-Harr premium polishing pads are mechanical polishing and restoration pads for concrete and terrazzo. We highly suggest dry use. These polishing pads are available in many diameters and grit sizes to accommodate many applications.

Maintaining Stone Polishing and Grinding Machine

What to do when inspecting floor machine -

After using the Lavina ELITE Machine, the operator must visually inspect the condition of the machine.Daily Inspection

- Inspect power cords, plugs and vacuum hoses, and loose bolts or screws. - Check the rubber buffers, elastic element and fixing of the holders Check that flanges holding the buffers or discs are securely mounted and locked in place. A gap seen there means that loose screws are fixing the holder. Screws must be tightened to use safely operate the grinder. Any loose screws results in serious damage to the equipment. Furthermore, consistently inspecting the screws that fix the Quick Change hold to the safety part is very important. If not secure, the holder will fly away if the buffers are compromised. Quick change should be clean.After 200 hours

Inspect all floor machine parts after every 200 hours of working time. Most importantly, inspect and clean the tool plate connections and vacuum hoses

- Inspect and clean the tool plate connections - Inspect the seal rings and bearings of the grinding units - Check the planetary belt

Check the guard assembly. Make certain the wheels are clean and rotate properly. Inspect the control buttons. If there are defective control parts, they should be replaced immediately. Replace worn vacuum hoses.

After 400 hours

- Replace the V‐rings - Check belts and bearingsAbout the Lavina ELITE Floor Machines

The Lavina ELITE polishing and grinding machines feature numerous upgrades. The first of these upgrades is an improved water system with 2 valves using water from a tank or different external source. Gravity is left to deliver the water instead of using a pump or misting system. As a result, these stone floor machines excel in wet grinding.

The ELITE machines have a dust-proof grinding head and low-friction chain gear planetary drive. Protection from dust makes the machines easier to clean and lengthens their service life.

They also have better dust collection efficiency when in comparison to older models of the Lavina floor grinding and polishing range. The efficient dust collecting comes from an adjustable skirt and flexible brush on the machine. The vacuum hose connection is also near the dust source.

These floor polishing machines have LED lights in both the front and the back to keep the work area visible during treatment.

The Lavina ELITE polishing and grinding machines feature numerous upgrades. The first of these upgrades is an improved water system with 2 valves using water from a tank or different external source. Gravity is left to deliver the water instead of using a pump or misting system. As a result, these stone floor machines excel in wet grinding.

The ELITE machines have a dust-proof grinding head and low-friction chain gear planetary drive. Protection from dust makes the machines easier to clean and lengthens their service life.

They also have better dust collection efficiency when in comparison to older models of the Lavina floor grinding and polishing range. The efficient dust collecting comes from an adjustable skirt and flexible brush on the machine. The vacuum hose connection is also near the dust source.

These floor polishing machines have LED lights in both the front and the back to keep the work area visible during treatment.